The humble master cylinder! an inherently simple device, the design of which hasn't taken on any major changes since brembo first patented the radial master cylinder back in 1985, setting a new standard in braking power, feel and consistency.

Following this PFM then came along and set the bar that bit higher with their three bearing lever design, allowing the lever to roll on the piston plunger, reducing stiction and side loading from the piston, allowing for a large bore, small lever ratio design, giving the smoothest lever feel on the market... currently - and that is where the techonology has remained for decades, I myself have wondered how the current state of the art could possibly be improved to no avail..... does it even need to be?

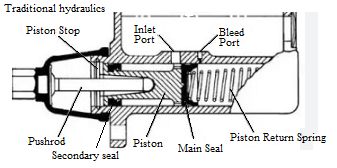

Well yes and no, the current standard does the job - however! most people on track have suffered with brake issues, not all, but some come from the master cylinder - as mentioned above, stiction and side loading of the piston as the seals move up and down the bore create a mushy feel and reduce power transfer to the calipers, meaning more braking effort from the rider is required.

As the brake fluid heats up it becomes harder for the seals to hold pressure, creating (one of several reasons for) more lever travel.

Seals swell when submerged in brake fluid, which varies for different fluid and seal materials, and means clearances for the reservoir bleed need to be built into the master cylinder which creates dead lever travel before the system pressurises.

When the rider releases the lever, fluid pushes past the seals to refil the system which produces a non linear response in braking pressure vs rider lever pressure, the current standard for race master cylinders is for a check valve (a shim that moves to allow fluid to flow in one direction only) is added behind the main seal to speed up the fluid flow into the pressurised side of the piston when the lever is relaxed - particularly if the rider isn't fully releasing the brakes, this creates a delay in the reaction of the system to the riders input, as the pressure on the caliper side decreases below ambient, the check valve opens, fluid flows, the check valve closes again and pressure stabilises...

the rider wont realise any of this is going on, these are events happening on a very small time frame - but all add up to create that elusive "brake feel"

And yes, the master cylinder is only one subsystem, within the whole, pads, lines, calipers, discs, even tyres contribute to brake feel!

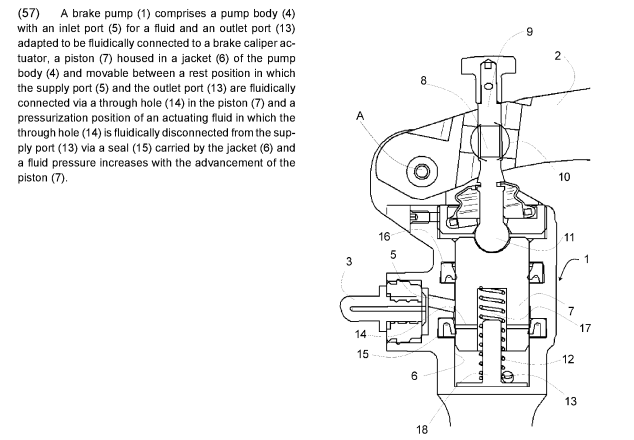

So what is this all about you ask? well as with most engineering problems, the simplest answer, is usually the best answer! and accossato have come up with the solution to these woes, with what I am in no doubt about, will eventually become the new standard in master cylinder technology. why have the seals mounted to a moving (wobbly) piston? when they can be fixed into the bore of the master cylinder!?

So what exactly have they done, why and how does it work so much better than a "normal" master cylinder?

As mentioned earlier - why have seals, that can bend and move, and change in size! and generally create lag and poor feel in the system, mounted to a piston, that also moves around and has nothing keeping it in a rigidly guided straight and perfect path up and down the bore - accossato have flipped this design on it's head and mounted the seals in the bore, so only the piston moves - at first glance this seems a bit "so what" but it has several key advantages.

- The seals still swell slightly when submerged in fluid - however now they grow away from the bleed hole, not towards it. this means the bleed hole/piston position can be set perfectly completely removing any free lever travel (or allowing a precise amount)

- Because the seals are now static in relation to the body, stiffer lip seals can be used, with a tighter fitting piston, completely isolating the pressurised and non pressurised sides of the piston, during braking - meaning pressure is now only, and instantly correlated with rider lever input

- Seal wear is decreased due to less pulling and pushing of the seals

- When the piston is pushing forwards and pressurising the system, the piston is also moving in the forwards motion of the seal lip, not against it, massively reducing seal drag and improving feel

- When the piston is pulling backwards, the action of the piston is working against the seal lip direction, helping to keep the system sealed until pressure is fully released from the lever, giving a linear response to the riders reduction in lever pressure

- Due to reverse action of the piston sealing the system, means a much faster release response - as suction literally pulls the pads back rather than relying on a passive reduction in pressure

- Due to reverse action of the piston sealing the system, means a much faster response if brake pressure is increased again.

The full patent can be viewed here:

https://worldwide.espacenet.com/publicationDetails/originalDocument?FT=D&date=20210721&DB=EPODOC&locale=en_EP&CC=EP&NR=3851347A1&KC=A1&ND=6

We have been very privelidged to be the first in the UK, and only a handful of race teams in the world to test the new GA master cylinder from Accossato! it is difficult to describe "brake feel" at first using the new master cylinder seemed a little alien - it wasn't anything "different" to how a master cylinder should feel.. in fact it is exactly how a master cylinder should feel!

The response is instant! for the first few corners, not being used to it, the bike was free wheeling before intended, your mind naturally adapts to what it is used to, and it is used to a delayed response from the master cylinder, which means you naturally release the lever more than needed... at first - but a few laps in and this new setup feels like home. Trail braking into tight hairpins genuinely became a pleasure, as brake pressure can now be so accurately applied and released, the transition from full braking to tipping in becomes smoother, allowing you to unload the front tyre progressively, from ridiculous amounts of stoppie inducing brake force without unsettling the front end and precisely controlling the amount of dive up to the apex was a revelation!

There was not a touch of fade in any race, qualifying, testing.. 180mph down to 40mph in 300 yards at the end of snetterton back straight is enough to test any braking system, and the system as a whole (GA master cylinder, PFM discs and PZ004 and EV2 pads) worked flawlessly... a little too flawlessly, as the front tyre was drifting sideways under the bridge - the Bridgestone R11 rubber (fitted due to cold conditions earlier in the day) was definitely no match for the amount of braking force available!

is this all necessary.. maybe not? are there faster riders out there, braking harder and lapping faster on lower spec systems? most definitely!

But still, it's bloody nice to have!

So in summary, this is genuinely one of those "why the hell weren't they designed like this in the first place!" moments.

This is a true step change in master cylinder technology, Accossato filed the Patent in 2021 - and have been working on developing this system over the past few yrs, only the likes of Pramac race team have had access to this technology, and it has eventually filtered down to ourselves, and now to the public! the downside to all of this development work is of course... cost - these are not cheap! with a retail price of £2800! it will still only be available to the lucky few..

Hold hope however, this technology will eventually filter down to the average rider. We are sure this technology will one day become the new normal and Accossato will be the inventor of the new state of the art for many yrs to come!